Factory inspection rooms

Role of Inspection Rooms

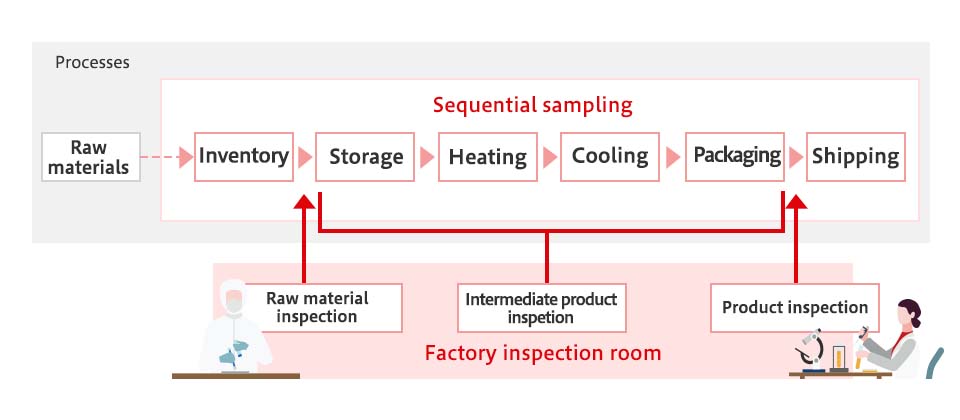

At production factories, besides the sequential sampling of finished products, food safety also is ensured by creating quality in each process and ensuring no defective products are sent to subsequent processes.

In production factory inspection rooms, general hygiene management and HACCP-compliant management are verified by inspecting raw materials, intermediate products, and finished products, as well as by conducting smear tests.*

If abnormalities are found in inspection results, it is possible to coordinate immediately with the person in charge of the production line affected and prevent the shipment of defective products. In addition, if a problem arises, we can immediately confirm the cause of the problem to contain its spread.

* Smear tests allow hygiene conditions in production processes to be ascertained by checking which microorganisms and allergens are present on cooking utensils, people’s hands, and a number of other surfaces.

HACCP Management System

This is management based on hazard analysis of critical control points that are continuously monitored, and the results recorded for each process, from raw materials to finished products.